一、研究所简介

以学院院长伍晓宇教授作为带头人,研究方向涵盖:微细电火花加工,微细电解加工,玻璃模压成形,模具表面改性,塑性微成形,单点金刚石超精密加工,离子束电子束微纳加工,微纳传感器件,非晶材料学及其工艺。本研究所具有扫描电子显微镜、激光共聚焦显微镜、超景深体式显微镜、原子力显微镜、X射线衍射仪、表面台阶仪、同步热分析仪、差式扫描量热仪、万能拉伸机、超精密电火花放电加工机、慢走丝线切割机、数控平面磨床、五轴数控机床、单点金刚石机床。具体研究方向及内容包括:

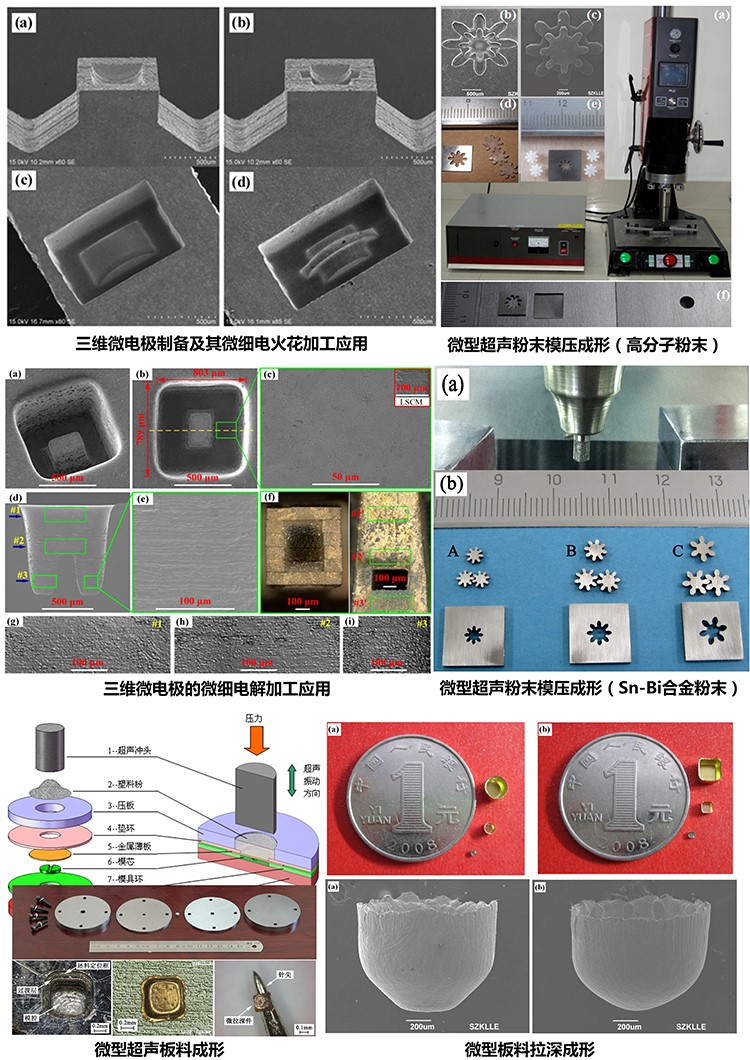

1:微细加工技术。研究微模具和微电极的新型制备工艺;研究新型微细电火花放电加工、微细电解加工、微细切削加工复杂金属微结构模具;研究微细加工过程中热、电、化学、光、声等多场耦合对非晶/纳米晶/超细晶材料交互作用的各种内在科学问题。近期主要研究微型双工位金属箔叠层成形工艺(Micro-DLOM),该工艺方法将飞秒激光切割、电火花线切割、电解线切割分别与电阻滑焊或高温真空压力热扩散焊进行组合制备三维叠层微型腔模具和三维叠层微电极;在此基础上,研究将三维叠层微电极用于微细电火花加工和微细电解加工以获得大深宽比整体式三维微型腔模具。

2:微成形技术。研究非晶、超细晶、纳米晶等微成形材料的新型制备工艺,揭示材料微结构与性能的演变规律;研究微成形的原理、新方法与新工艺,阐明微成形过程中的尺度效应机理,提出微型零件的质量控制方法。近期以大批量、低成本和高效率量产微零件为目标,研究粉末电阻热微体积成形(Micro-RWM)、微型超声粉末模压成形(Micro-UPM)、微型超声塑化柔性冲头板料成形(Micro-USF)、微型超声塑化柔性冲头挤压成形(Micro-UFE)、微型高分子粉末介质板料成形(Micro-PPF)等新型微成形技术。

3:自动化装备。研制微型切削加工装备;研制面向微细电火花和微细电解加工的专用高频脉冲电源及其配套装置;研制自动化生产线上装备。近期研究、改进和推广PPCNC微型数控车/铣床;研制生产线上的各种非标机电一体化装备。

二、代表性研究成果

[1] Bo Wu, Xiaoyu Wu*, Jianguo Lei*, Bin Xu, Shuangchen Ruan, Jinming Zhong. Study on machining 3D micro mould cavities using reciprocating micro ECM with queued foil microelectrodes [J]. Journal of Materials Processing Technology, 2017, 241:120-128.

[2] Wenyan Luo, Xiaoyu Wu*, Jianguo Lei*, Bin Xu, Rong Cheng, Shuangchen Ruan. Micro resistance weld moulding to fabricate CuSn33 alloy parts [J]. Journal of Materials Processing Technology, 2016, 231:137-142.

[3] Jianguo Lei, Xiaoyu Wu*, Bin Xu*, Zhentao Zhao, Shuangchen Ruan, Rong Cheng. Laminated fitting fabrication of Cu-Sn composite 3D microelectrodes and elimination of ridges on the machined surface of 3D micro-cavities [J]. Journal of Materials Processing Technology, 2015, 225:24-31.

[4] Wenyan Luo, Xiaoyu Wu*, Shiyun Wu, Bin Xu, Rong Cheng, Shuangchen Ruan. Micro-ultrasonic powder molding of Sn-Bi/Cu composite micro parts in semisolid form [J]. Journal of Materials Processing Technology, 2015, 223:313-318.

[5] Bin Xu, Xiaoyu Wu*, Jianguo Lei, Rong Cheng, Shuangchen Ruan, Zhenlong Wang. Laminated fabrication of 3D micro-electrode based on WEDM and thermal diffusion welding [J]. Journal of Materials Processing Technology, 2015,221:56-65.

[6] Shiyun Wu, Xiaoyu Wu*, Bin Xu, Rong Cheng, Feng Luo, Shuangchen Ruan. A micro-ultrasonic powder moulding method to fabricate Sn-Bi alloy micro parts [J]. Journal of Materials Processing Technology, 2014, 214: 2668-2675.

[7] Gong Feng, Chen Shunhua, Ran Jiaqi, Yang Zhi, Ma Jiang*. Tuning the performance of bulk metallic glasses by milling artificial holes [J]. Materials Science & Engineering A. 2016, 668: 50-54.

[8] Ma Jiang, Liang Xiong, Wu Xiaoyu, Liu Zhiyuan, Gong Feng*. Sub-second thermoplastic forming of bulk metallic glasses by ultrasonic beating [J]. Scientific Reports. 2015, 5: 17844.

[9] Xiong Liang, Jiang Ma*, Xiaoyu Wu*, Bin Xu, Feng Gong, Jianguo Lei, Taijiang Peng, Rong Cheng. Micro injection of metallic glasses parts under ultrasonic vibration [J]. Journal of Materials Science & Technology, 2017, DOI: 10.1016/j.jmst.2016.10.012.

[10] Wenwei Lai, Xiaoxing Zeng, Jian He, Yuanlong Deng*. Aesthetic defect characterization of a polymeric polarizer via structured light illumination [J]. Polymer Testing, 2015,51:51-57.