- About

- Research Platform

- Guangdong Provincial Key Laboratory of Micro/Nano Optomechatronics Engineering

- Shenzhen Key Laboratory of Advanced Manufacturing Technology for Mold & Die

- Shenzhen Key Laboratory of Electromagnetic Control

- Shenzhen Autonomous Unmanned System and Intelligent Operation Joint Laboratory

- Shenzhen Key Laboratory of Urban Rail Transit Technology

- Guangdong Provincial Key Laboratory of Micro/Nano Optomechatronics Engineering

- Research Institutes

- Institute of Semiconductor Manufacturing Research

- Institute of Precision Machining and Forming Technology

- Institute of Nano-surface Science and Engineering

- Additive Manufacturing Institute

- Institute of Automation Shenzhen University

- Institute of Intelligent Equipment and Detection Technology

- Institute of Human Factors Engineering

- Institute of Power Electronics and Power System Control Technology

- Institute of Robotics and Intelligent Equipment

- Institute of Semiconductor Manufacturing Research

Introduction to the Institute

With Professor Wu Xiaoyu, the dean of the college, as the leader, the research direction covers micro-EDM, micro-electrolytic machining, glass molding, mold surface modification, plastic micro-forming, single-point diamond ultra-precision machining, and ion beam electron beam micro-forming. Nanofabrication, micro-nanosensor devices, amorphous materials, and their technology. The Institute has scanning electron microscopes, laser confocal microscopes, super depth-of-field stereo microscopes, atomic force microscopes, X-ray diffractometers, surface profilometers, synchronous thermal analyzers, differential scanning calorimeters, universal stretching machines, an ultra-precision electric spark discharge machine, a slow wire cutting machine, a CNC surface grinder, a five-axis CNC machine tool, and a single-point diamond machine tool. Specific research directions and contents include:

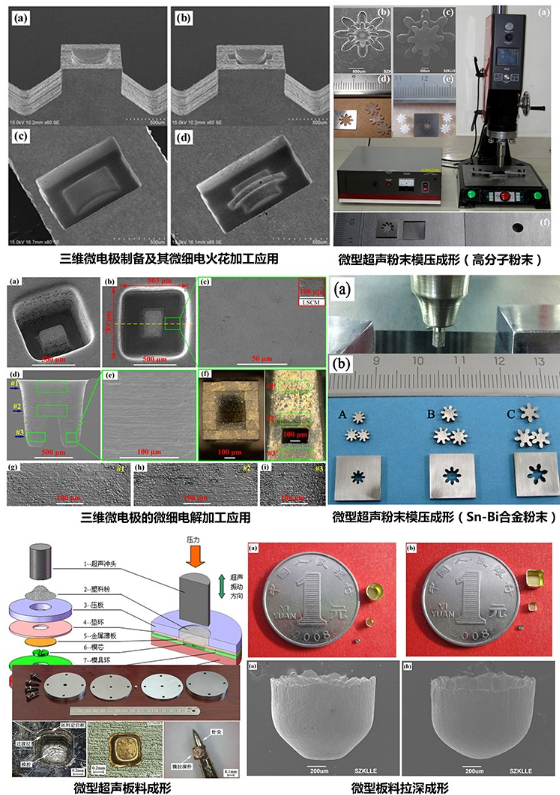

1. Micro-processing technology: Research on new preparation techniques of micro-molds and micro-electrodes; research on new micro-EDM, micro-electrolytic machining, and micro-cutting complex metal microstructure molds; research on multi-field coupling of heat, electricity, chemistry, light, and sound in the process of micro-machining Various intrinsic scientific questions on the interaction of amorphous/nanocrystalline/ultrafine- grained materials. Recently, the research mainly focuses on the micro double-station metal foil lamination forming process (Micro-DLOM), which combines femtosecond laser cutting, wire electric discharge cutting, and electrolytic wire cutting with resistance sliding welding or high temperature vacuum pressure thermal diffusion welding respectively. Prepare three-dimensional laminated microcavity molds and three-dimensional laminated microelectrodes; on this basis, study the use of three-dimensional laminated microelectrodes for micro-EDM and micro-electrolytic machining to obtain a large aspect ratio monolithic three- dimensional microcavity mold.

Research team: Wu Xiaoyu, Xu Bin, Guo Dengji, Lei Jianguo

2. Micro-forming technology. Study the new preparation process of micro-forming materials such as amorphous, ultra-fine crystal, and nano-crystal, reveal the evolution law of material microstructure and properties, study the principle, new method, and new process of micro-forming, and clarify the mechanism of scale effect in the process of micro-forming to propose a quality control method for micro-parts. In the near future, with the goal of mass production of micro parts in large quantities at low cost and high efficiency, research will be conducted on powder resistance thermal micro volume forming (Micro-RWM), micro ultrasonic powder moulding (Micro-UPM), micro ultrasonic plasticized flexible punch sheet forming (Micro-USF), micro-ultrasonic plasticized flexible punch extrusion (Micro-UFE), micro-polymer powder medium plate forming (Micro-PPF) and other new micro-forming technologies.

Research team: Lou Yan, Cheng Rong, Gong Feng, Luo Feng, Liu Zhiyuan, Ma Jiang, Liang Xiong, Ran Jiaqi, and Zhao Hang

3. Automation equipment. Develop micro-cutting processing equipment; develop special high-frequency pulse power supplies and supporting devices for micro-EDM and micro-electrolytic machining; and develop automated production line equipment. Recent research, improvement, and promotion of PPCNC micro CNC turning and milling machines; research and development of various non-standard electromechanical integration equipment on the production line.

Research team: Zhang Guoqing, Lu Yanjun, Huang Peng, and Xu Teng

Representative research results

[1] Bo Wu, Xiaoyu Wu*, Jianguo Lei*, Bin Xu, Shuangchen Ruan , Jinming Zhong. Study on machining 3D micro mold cavities using reciprocating micro ECM with queued foil microelectrodes [J]. Journal of Materials Processing Technology, 2017, 241:120-128.

[2] Wenyan Luo, Xiaoyu Wu*, Jianguo Lei*, Bin Xu, Rong Cheng, Shuangchen Ruan . Micro resistance weld molding to fabricate CuSn33 alloy parts [J]. Journal of Materials Processing Technology, 2016, 231:137-142.

[3] Jianguo Lei, Xiaoyu Wu*, Bin Xu*, Zhentao Zhao, Shuangchen Ruan , Rong Cheng. Laminated fitting fabrication of Cu-Sn composite 3D microelectrodes and elimination of ridges on the machined surface of 3D micro-cavities [J]. Journal of Materials Processing Technology, 2015, 225:24-31.

[4] Wenyan Luo, Xiaoyu Wu*, Shiyun Wu, Bin Xu, Rong Cheng, Shuangchen Ruan . Micro-ultrasonic powder molding of Sn-Bi/Cu composite micro parts in semisolid form [J]. Journal of Materials Processing Technology, 2015, 223:313-318.

[5] Bin Xu, Xiaoyu Wu*, Jianguo Lei, Rong Cheng, Shuangchen Ruan , Zhenlong Wang. Laminated fabrication of 3D micro-electrode based on WEDM and thermal diffusion welding [J]. Journal of Materials Processing Technology, 2015,221:56-65.

[6] Shiyun Wu, Xiaoyu Wu*, Bin Xu, Rong Cheng, Feng Luo, Shuangchen Ruan . A micro-ultrasonic powder molding method to fabricate Sn-Bi alloy micro parts [J]. Journal of Materials Processing Technology, 2014, 214: 2668-2675.

[7] Gong Feng, Chen Shunhua , Ran Jiaqi, Yang Zhi , Ma Jiang*. Tuning the performance of bulk metallic glasses by milling artificial holes [J]. Materials Science & Engineering A. 2016, 668: 50-54.

[8] Ma Jiang, Liang Xiong , Wu Xiaoyu , Liu Zhiyuan , Gong Feng*. Sub-second thermoplastic forming of bulk metallic glasses by ultrasonic beating [J]. Scientific Reports. 2015, 5: 17844.

[9] Xiong Liang, Jiang Ma*, Xiaoyu Wu*, Bin Xu, Feng Gong, Jianguo Lei, Taijiang Peng, Rong Cheng. Micro injection of metallic glasses parts under ultrasonic vibration [J]. Journal of Materials Science & Technology, 2017 , DOI: 10.1016/j.jmst.2016.10.012.

[10] Wenwei Lai, Xiaoxing Zeng, Jian He, Yuanlong Deng*. Aesthetic defect characterization of a polymeric polarizer via structured light illumination [J]. Polymer Testing, 2015, 51:51-57.